DESCRIPTION:

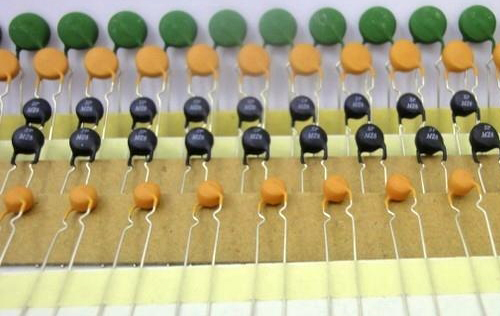

¡ö XXMZA series PTC thermistors are used in various types of fluorescent lamps, electronic ballasts and electronic energy-saving lamps as preheating-starting components. Preheating of the electrodes lengthens the life of the lamps and the number of switching cycles significantly.

¡ö With rich experience, we offer PTC thermistors for time delay and switching with high quality and competitive price.

¡ö Many famous lighting producers join our customers list , such as Philips¡¢GE£¨China£©¡¢IKEA¡¢Megaman¡¢Osram£¨China£©¡¢TCL

¡ö See below Fig.1, Immediately after power is switched on, the PTCR is cold and it's resistance is far lower than C2's. The current through C1 and Rt forms a return circuit to preheat the filament. About 0.4-2s later, Rt's joule heat temperature exceeds Curie point Tc and the PTCR will switch. Its resistance is far higher than C2's. The current passes through C1 and C2 to form a return circuit, which causes LC resonance and produces high voltage to light the fluorescent tube.

|

XX

¡ª ¢Ù |

MZ

¡ª ¢Ú |

A

¡ª ¢Û |

6 — ¢Ü |

H — ¢Ý |

101 — ¢Þ |

M — ¢ß |

650

¡ª ¢à |

Notes£º

¢Ù XIXI Co.

¢Ú PTC thermistor

¢Û For electronic Ballast or energy-saving lamp starter

¢Ü Diameter of PTCR before sinter: 6-Φ6

¢Ý Curie temperature£ºE-50¡æ£» F-65¡æ£» H-75¡æ£» I-85¡æ£» M-105¡æ£» S-115¡æ

¢Þ Resistance value at 25¡æ£¨R25¡æ£©£º60R-60Ω£»101-100Ω

¢ß R25¡æ Tolerance£ºM£¨±20%£©£»H£¨±25%£©£»N£¨±30%£©

¢à Maximum voltage : 650-650V

| Part No. | Curie Temperaure TC ( ¡æ ) |

Nominal Zero-Power Resistance R25¡æ ( Ω ) |

Max. Voltage Vmax ( V ) |

Dimensions ( mm ) | ||

| Dmax | Hmax | Φd | ||||

| XXMZA-4H151M500 | 105 ± 7 | 150 ± 30% | 500 | 5.0 | 4.5 | 0.6 |

| XXMZA-4H221M600 | 220 ± 30% | 600 | ||||

| XXMZA-4H331M650 | 330 ± 30% | 650 | ||||

| XXMZA-4H401M650 | 400 ± 30% | 650 | ||||

| XXMZA-4M151M500 | 105 ± 7 | 150 ± 30% | 500 | |||

| XXMZA-4M331M650 | 330 ± 30% | 650 | ||||

| XXMZA-4M401M650 | 400 ± 30% | 650 | ||||

| XXMZA-4M651M650 | 650 ± 30% | 650 | ||||

| XXMZA-6M151M600 | 105 ± 7 | 150 ± 30% | 500 | 6.5 | 5.0 | 0.6 |

| XXMZA-6M221M650 | 220 ± 30% | 650 | ||||

| XXMZA-6M331M650 | 330 ± 30% | 650 | ||||

| XXMZA-6M401M650 | 400 ± 30% | 650 | ||||

| XXMZA-8H152M650 | 75 ± 7 | 150 ± 30% | 650 | 8.0 | 5.0 | 0.8 |

| XXMZA-8H221M650 | 220 ± 30% | 650 | ||||

| XXMZA-8H331M800 | 330 ± 30% | 800 | ||||

| XXMZA-8H401M900 | 400 ± 30% | 900 | ||||

| XXMZA-9H152M650 | 75 ± 7 | 150 ± 30% | 650 | 9.0 | 5.0 | 0.8 |

| XXMZA-9H221M650 | 220 ± 30% | 650 | ||||

| XXMZA-9H331M800 | 330 ± 30% | 800 | ||||

| XXMZA-9H401M900 | 400 ± 30% | 900 | ||||

1. 75¡æ, 85¡æ and 105¡æ series PTCR are mostly used.

2. The data is only for reference, you can forward your detailed requirements if possible.

3. We have obtained the SGS test report about the content of Lead¡¢Cadmium¡¢Mercury¡¢ Hexavalent Chromium¡¢PBBs¡¢PBDEs in the XXMZA series PTCR.